Projection screens in general

Projection screens are the most ideal way to display the results of professional projection technology!

When we talk about projection, we have to be aware that quality depends on more than the projector itself!

Stage projection technology has developed extensively in the past decade. The digital, high- performance projectors are capable of projecting video instead of still images without distortion, even onto arched surfaces.

When using high quality projection screens the quality of the projection depends on numerous factors, e.g. the quality of the projector itself, ambient lighting, and projection distance.

Outdoor locations with daylight have especially strict conditions of projection!

Don’t settle for half-baked solutions!

When projection is needed on stages and various events the source of the projection, the projector itself and its technical parameters (ANSI-Lumen [1], colour spectrum and colour fidelity [2], contrast [3], gain [4], gain diagram [5], beam angle and half gain angle [6], black value [7]) and alternative solutions like LCD or 1, 2 or 3-chip DLP projectors and their data is given intensive attention.

The projection surface, the “medium” itself, however, receives very little of said attention. With the development of light sources the LEDs more and more widely used in studio and stage technology have an effect on the projection surfaces as well.

Use a professional projection surface!

Be a professional! Choose the ideal solution!

New technologies bring new requirements for the projection surfaces as well. When a lighting director says they use “an opera screen”, they usually can’t answer the question of which one it is exactly.

Nowadays projection screen is a term that can mean several different projection screens with different characteristics, e.g. “opera white, perforated, light blue, milky matte” etc.

The Gerriets [8] range of projection screens offer front, front and rear, and rear projection screens developed for numerous use cases apart from the OPERA® screen.

Get to know the characteristics, possibilities, and limitations of the screens, as well as the secret to their longer lifespan!

PVC/thermoplastics

Most projection screens are made of PVC. PVC is an amorphous thermoplastic. It’s a hard and brittle white material that only becomes softer, easier to form and fit for technical use by using additives that soften and stabilize it. Further additives make it harder to burn.

Preparation of the screen

The high-frequency welding process is the most modern, effective, and highest quality welding method available on the market. During several production steps smooth, almost invisible seams are created. Lacquered films and other PVC films can also be produced using this process. We can create inflatable films with valves, for example.

Screen size

With the use of high-frequency welding technology almost any size can be produced. As for height, however, the soft PVC projection screens have a physical limit, since the entire weight of the material rests on the upper part of the screen which can cause it to stretch. For greater heights we suggest using reinforced projection screens, but in these cases rear projection is not recommended..

Width has no theoretical limit, you only have to take the total weight of the projection screen into account. When choosing the size of the projection screen a reasonable width/height ratio has to be considered, as the soft PVC projection screen tends to become thinner in the middle if the height is larger than the width.

Cleaning

To ensure a longer lifespan the screens have to be cleaned using a special PVC-cleaning agent and a microfiber cloth. The cleaning agent must not contain solvents and can’t harm the material of the PVC film!

Repair

On-site repair of smaller damages shall be performed using a really strong special PVC adhesive and patching pieces of the screen in question. To avoid any misunderstandings please keep in mind that even smaller repairs will be visible, especially with screens projected on from the back.

May we help make the choice?

[1] ANSI-Lumen: The unit measuring the lighting capacity of the projector. ANSI-Lumen is the comparative measurement of the light intensity of projectors. Light intensity is calculated from the amount of light (lux) and the area of the illuminated surface (m²).

[2] Colour spectrum and colour fidelity: The colour spectrum shows whether the reflection or transmission of light is uniform across all ranges. The colour spectrum shows the reflection or transmission of visible light (approx. 380-780 nanometres) on the entire image surface. The reflection and transmission characteristics of visible colours on the projection surface can differ greatly regarding certain colour ranges.

As opposed to the luminance factor the median value on the entire screen is measured in the nanometre range when measuring the colour spectrum, thus a low reflection/transmission value doesn’t automatically translate to low luminance. The amount in which a projection screen shows colours is less determined by the amount or intensity of reflection or transmission, and is more dependent on their uniformity across different wavelengths.

The more homogenous the measured values and the smoother the graph is on the shown colour spectrum, the higher the colour fidelity of the given projection screen. The diagram shows almost perfect colour fidelity for the Gammalux High End projection screen.

[3] Contrast: It defines the relation between black and white. Contrast is good if the viewer sees black parts of the image as black, and white parts as white.

To measure the contrast ratio a rectangle is projected with eight black and eight white fields, and the light reflected from the projection screen is measured. The median of the eight white and eight black measuring points is defined, and these are sorted into ratio pairs.

This value is the contrast ratio. Under normal auditorium circumstances (ambient lighting of about 200 lux) the following values are recommended: contrast ratios between 5:1 and 10:1 count as bad, by a ratio of 20:1 the quality is regarded good.

[4] Gain: Describes the effectiveness of a projection surface. The DIN 19045 standard describes how the lighting performance of a surface can be calculated in relation to a predefined reference surface (white in accordance with standard DIN 50339).

This white reference surface is made of barium-phosphate, basically a sheet of white chalk. For this white chalk surface used as a reference the gain is 1. The gain is always a value measured in relation to this reference surface. This makes gain values higher than 1 possible. In these cases the projection surface reflects more light (front projection) or lets more light through (rear projection) than the sheet of white chalk.

Gain is measured from various angles. Gain is the highest when the light reaches the surface vertically and the viewers look at it from the same axis as well. The projection axis and the optical axis match in these cases. The viewing angle is 0°. This is the position to measure maximum gain. However, the farther the viewer is located from the projection axis the larger the viewing angle, and typically the smaller the gain of the reflected light.

[5] Gain diagram: Shows the gain in relation to the viewing angle. The flatter the curve, the more even the distribution of the projected surface’s gain. The steeper the curve, the more likely the projection screen is to produce so-called hot-spots (lighter patches in the middle of the image), which makes it unsuitable for specific use cases (e.g. projections with soft transitions).

[6] Beam angle and half gain angle: The beam angle of an image surface is the viewing limit in accordance with standard DIN 19045. This viewing limit is defined as 40° to the left and right of the 0 angle or projection axis.

The half gain angle shows the angle in relation to the axis where the ß gain value is 50% of its maximum. This data is only rarely mentioned as a plus characteristic next to the gain value when describing a projection screen.

[7] Black value: Gives the intensity of blacks in the projected image. The black value is affected by both the light source of the projector and the projection surface. The optimal black value would be the theoretical zero percent reflection or transmission of the incoming light.

[8] Gerriets is a constantly growing company, present in 19 countries with its subsidiaries and distributors. Since its establishment in 1946 Gerriets became a professional company serving stage, event, and exhibition needs.

Its activity branches out to every area: production of curtains, sheeting, scenic materials, ultrawide textiles, horizontal fabrics, decorative fabrics, stage velvets, effect materials, stage equipment, for example curtain-moving rail systems.

A four-season congress centre has been constructed in Balatonfüred; during the erection of the congress centre we performed the entire stage technology design and construction.

Project details

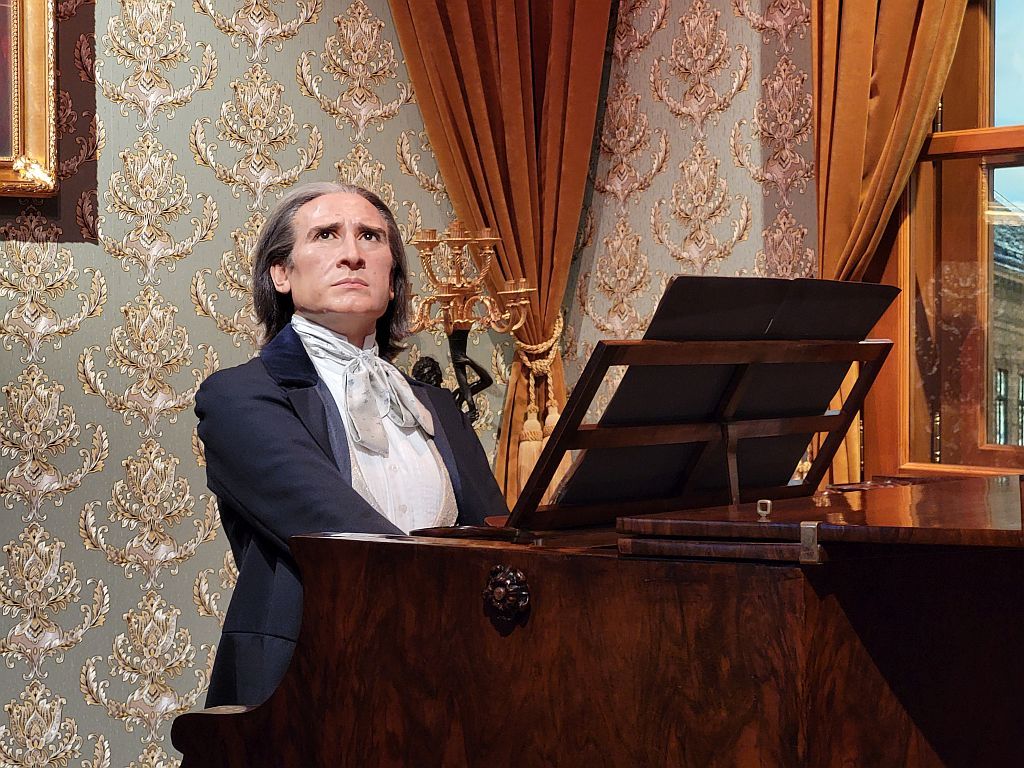

The capital's attraction will feature 51 lifelike wax figures of international and Hungarian celebrities, with 17 Hungarians among them. We were commissioned to create the installations for the figures; we had to make curtains for 4 installations ...

Project details

Do you need a digital

signage solution?

As the official distributor of Hisense business displays in Hungary, we can help you find the best solution.

Do you need a digital

signage solution?

As the official distributor of Hisense business displays in Hungary, we can help you find the best solution.